Believe it or not, you can reduce or expand a tube or pipe to fit into another piece. Does it sound like magic? Thanks to the Huth 1673 swager, reducer, expander machine, you can make one-of-a-kind end forms.

Swaging (pronounced “swedging”) means reducing or expanding tubing and pipes. This cold-working metal process is used to create end forms that connect pipes and tubes together (or to another piece of equipment). The Huth 1673 portable swager-expander allows you to create many different end forms to connect your pipes and tubes.

Precision End Forms

As the old saying goes, it's hard to fit a square peg in a round hole. It's also hard to connect two pieces of tubing together if they're the exact same size or slightly different shapes. You need a pipe expander or pipe reducer to create a smaller end form. The Huth 1673 portable swager-expander allows you to create one-of-a-kind end forms.

With the Huth 1673 pipe expander machine, you can repeatedly create a precision end form on pipes and tubes. It’s ideal for manufacturing components for many different structures. The 1673 is ideal for:

- Flagpole manufacturing

- Industrial and municipal light mounting

- Gating and fencing fabrication

- Agricultural manufacturing and applications

- Electrical conduit fabrication

- Much more!

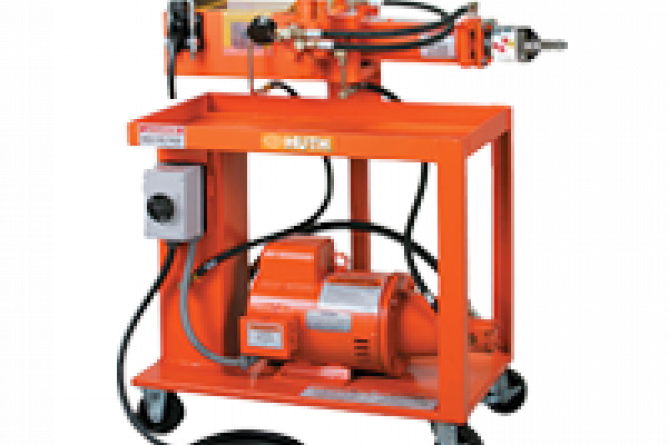

The Huth 1673 machine comes mounted on its very own easy-wheeling cart. Move it around your shop as needed for ready access. The Huth 1673 pipe reducer, expander, and swager allows your team to form slip joints, ball joints, flares, and flanges. Perform doming and reducing from any place in your shop.

Sometimes it's easier to learn from a demonstration. Below is the Huth 1673 demo video that shows how this magic little machine can change your game. Seeing is believing!

Huth 1673 Demonstration Video

The Huth 1673 handles expanding and forming 16-gauge tubing through schedule 40 pipe. It even works on heavy-walled materials (we recommend using a little grease to ease the process). It's incredibly versatile and powerful, making it a wise investment for your shop.

Reduce or expand pipe and tubing with a simple change of the swage die. The Huth 1673 pipe reducer-expander does it all. Need more details on the possibilities? Here are all the end forms you can create with the Huth 1673:

- Enlarge the end diameter on tubes and pipe with the swage die

- Create a 45-degree flare or flange

- Create a flat, 90-degree flare or flange

- Create a male ball joint or female ball joint

- Perform tube reduction

- Use the AccuSizer for precision sizing

How to Create End Forms with the Huth 1673 Swager-Expander-Reducer Machine

Wondering how to use the Huth 1673 machine? We highly recommend following the detailed instructions in your machine manual for more information, but below are abbreviated instructions for the most popular end forms. Click to watch the demo videos for each form, and remember that these are just brief overviews of the steps.

Explore these magical possibilities and more with the Huth 1673 swager!

Enlarging with the Swage Die

Follow these steps to enlarge a tube or pipe to a deep inside diameter using the swage die. Note on swaging depth: Huth has tooling for normal (approx. 2 inches) or deeper (up to 4 inches on tube OD's over 1 ½ inches) swages.

- Install the swage die to the Huth 1673 machine by screwing it onto the cylinder shaft in the swage box.

- Secure your tube or pipe with the proper clamping collets.

- Close the safety guard. Then operate the ram.

- Move the cylinder forward slowly until the tool enters the tubing or piping.

- Continue to move the shaft forward until the tool reaches the desired depth.

Enlarging with the Swage Die Demo

Using the Reducing Die

Follow these steps to use the Huth 1673 machine to reduce the inside diameter of a tube or pipe.

- Install the reduction swage die by screwing it onto the cylinder shaft of your Huth 1673 machine.

- Secure your tube or pipe with the proper clamping collets.

- Close the safety guard. Then operate the ram.

- Move the cylinder forward slowly until the tool slides over the tube or pipe.

- Continue to move the shaft until the machine has formed the reduction.

- Don’t go too deep, or it will crush the tube or pipe!

Using the Reduction Die Demo

Create a 45-Degree Flare or Flange Using the Huth 1673 Machine

To create a 45-degree end flare or flange, follow the steps below. Keep in mind that this is a process example, and you would use the same process for the different pipe diameters.

- To create a 45-degree flare, start by attaching tool 853, onto the 815-die holder, with the 45-degree flare facing forward.

- Insert the tube or pipe and clamp down. Place safety guards.

- Slowly bring the tool up to the tube or pipe.

- Tap the control handle on the 1673 machine and move the cylinder shaft forward until the desired flare is formed.

- Retract the cylinder shaft and remove the tube or pipe.

Create a 45-Degree Flare or Flange Demo

Create a Flat Flare or Flange

Follow these steps to create a flat flare or flange, also known as a 90-degree flare or flange, on your Huth 1673. The 90-degree or flat flare creation process requires two operations.

- Follow the directions above first to create a 45-degree flare using your Huth 1673 machine.

- Retract the cylinder but leave the tube or pipe in place.

- Reverse tool 853 on the machine.

- Use the control handle to slowly bring the tube or pipe forward until the flare forms a flat surface.

- Retract the cylinder shaft and remove the tube or pipe.

Create a 90-Degree Flat Flare or Flange Demo

Create a Female Ball Joint

Follow these steps to create a female ball joint using the Huth 1673 machine.

- Attach the proper female tool to tool 815 and secure the tube or pipe into clamps with proper collets. Place safety guards.

- Slowly bring the tool forward until it starts forming the joint.

- Tap the control handle on your Huth 1673 machine until it bottoms out on the ridge.

- Retract the cylinder shaft and remove the tube or pipe.

Create a Female Ball Joint Demo

Create Male Ball Joint

To create a male ball joint, there are two necessary operations on your Huth 1673 machine.

- Attach the proper male ball joint tool to the end of the cylinder.

- Secure the tube in the collet holder and place safety guards.

- Slowly insert the tool forward and tap until the tool reaches the second marking line.

- Retract the tool.

- Dome the end of the male ball joint by using the 557 die with the domer die attached to the 815 to create a completed male ball joint.

Create a Male Ball Joint Demo

Use the AccuSizer for Precision Pipe Expansions

Huth’s AccuSizer system allows you to dial-in precise expansions every time. Use the AccuSizer with the 1673 to quickly and efficiently create some of the following end forms:

Create a 45-degree Flare with the AccuSizer

The AccuSizer allows you to make a flared end form very close to a bend in a pipe or tube.

- Attach the 508 arbor with the 499 arbor tip and 440 flaring segment set.

- Insert the tube or pipe and clamp down. Place the safety guards.

- Slowly bring the tool up to the tube or pipe.

- Tap the control handle and move the cylinder shaft forward until the desired flare is formed in the pipe.

- Retract the cylinder shaft and remove the tube or pipe.

Create a 45-degree Flare with the AccuSizer

Create Male and Female Ball Joints with the AccuSizer

You can also use the AccuSizer to create male and female ball joints.

- Use the correctly-sized arbor and tip (both male and female are made with the same segment set).

- Install the proper ball joint segment set according to your tube or pipe diameter.

- Insert the tube or pipe into the base of the segment set to create a male ball joint and clamp down. Or, if you're making a female ball joint, insert the tube or pipe into the groove on the ball.

- Place the safety guards.

- Tap the control handle and move the cylinder shaft forward until the desired flare is formed.

- Retract the cylinder shaft and remove the tube or pipe.

The Huth 1673 pipe expander, reducer, and swager is truly a must-have. This "magical" machine can help you fit pipes and tubes for a precise connection. If you want to know more, don't hesitate to get in touch with our knowledgeable and helpful staff today!